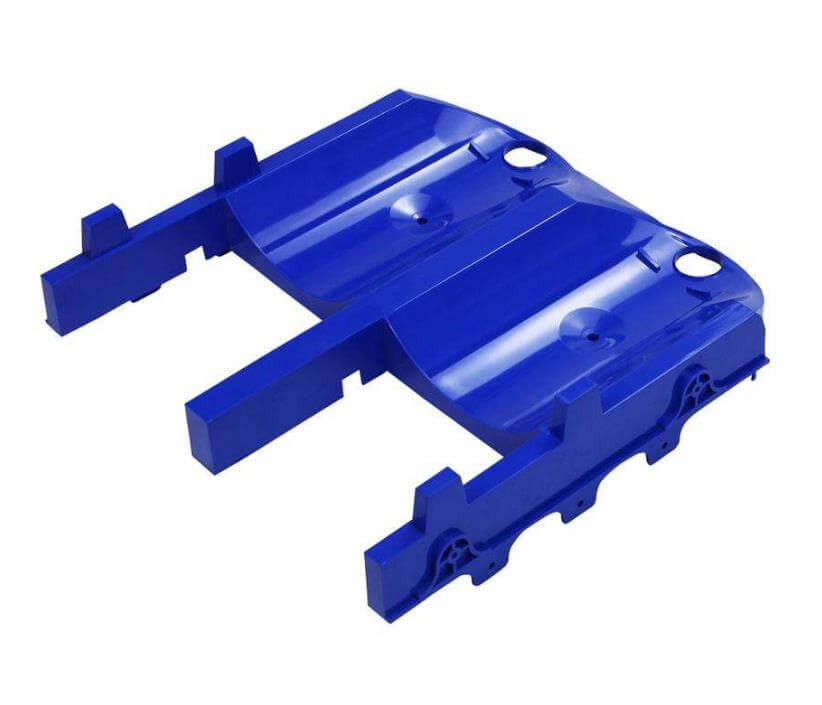

Custom Injection Molding Service for Parts

We provide exceptional injection molding expertise to provide comprehensive technical guidance and tooling options for your project. Get custom-molded prototypes and production parts in as few as 10 business days.

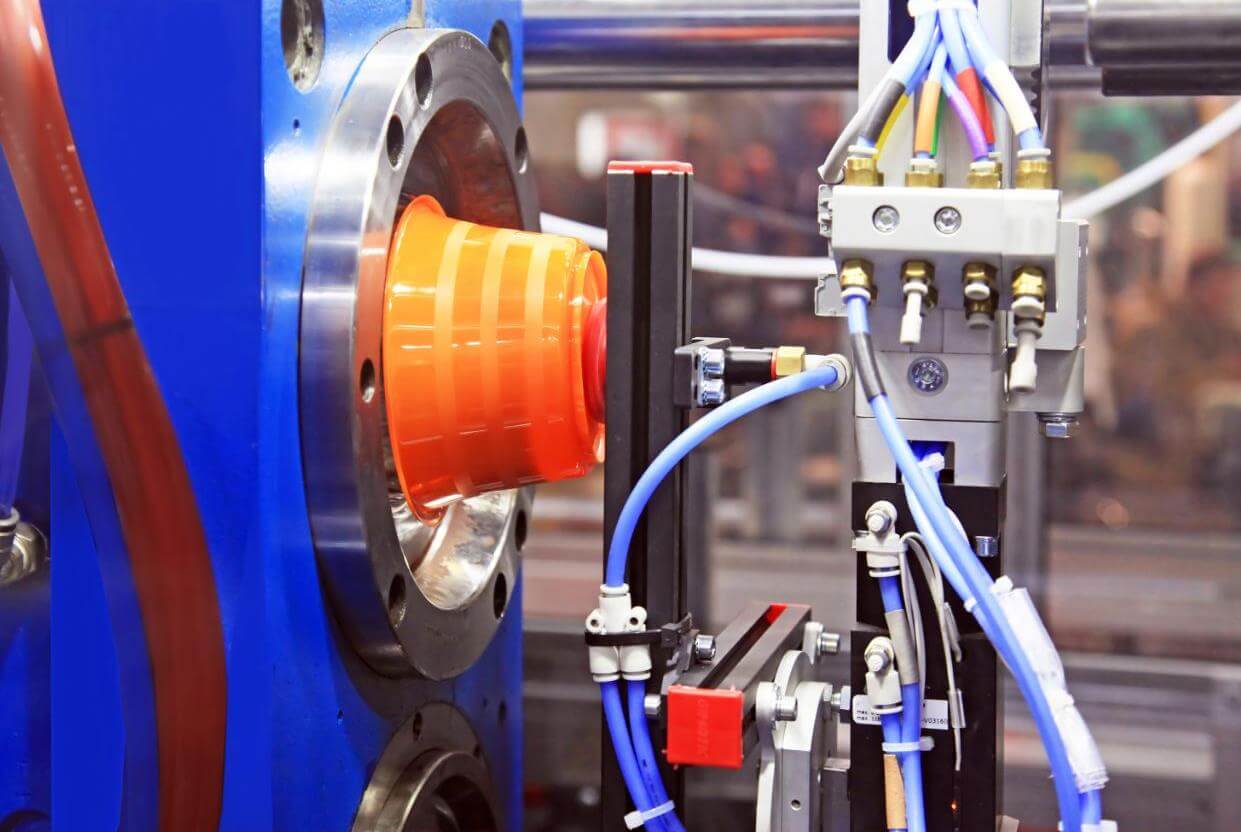

Understanding Injection Molding Processes

- Injection molding is injecting heated plastic materials into a mold and then cooling and solidifying them to make the shape from the mold also the final product typically requires little to no secondary finishing.

- The principal advantage of injection molding is the ability to scale mass production, Injection molding leverages repetition, and consistency can be made same part is being created thousands or even millions of times in succession.

- It has proven especially valuable to those in the consumer product development sector, since plastics are a primary component of many consumer products, and take a large part in the area of plastic processing as the preferred manufacturing process for plastic molding projects.

Injection Molding Solution Companies

According to prototyping the part itself to specification, usually prototyped in a different material, a wide variety of products are manufactured using injection molding, which varies greatly in size, complexity, and application. We provide the most popular custom injection molding processes in the market, allowing us to create detailed custom injection molding parts quickly and efficiently.

Process selection based on material:

- Plastic Injection Molding

- Silicone Rubber Molding

- Metal Injection Molding

Addition Injection Molding Options:

- Over molding

- Insert molding

Start Your Project Today

At ProtoAces, custom parts services are our AS9100-certified CNC machining facilities designed for moving from rapid prototyping to full-scale production of end-use components. With 50+ CNC machines, we are able to rapidly precision machine your custom-made parts, ensuring your parts are shipped on time, every single time.

PROVIDE EMERGENCY MACHINING SERVICES ON ANY REQUEST.

How to work with us

Send parts design files

To start, send us an email file in the supported format. Remark the material and manufacturing process of your choice.

Confirm specs and get a quotation

Get a fair estimate of cost and turnaround time. Configure your part specifications and select a lead time that suits your schedule.

Start Production

After you place an order, we will select the best manufacturer for your order, and take full responsibility for making sure your parts are manufactured according to our standards, production begins immediately.

Parts are Shipped!

Our digital manufacturing process allows us to produce parts as fast as 1 day. Follow up on all order logistics and communications, ensuring your parts arrive on time.