Online Provides CNC Milling Services

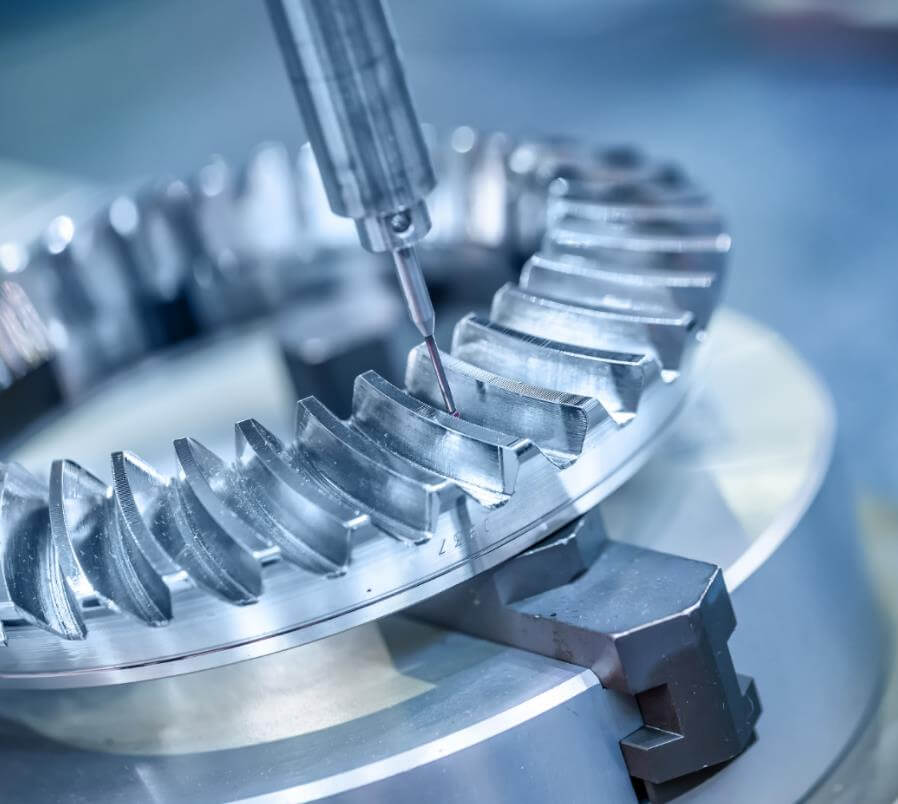

Digital technology makes the world more and more advanced, especially CNC milling machines make complex prismatic shapes and flat surfaces for a limitless variety of commercial and industrial products.

To understand CNC Milling Parts Service

- CNC milling is a computer-controlled, machining process that employs computerized controls and rotating cutting tools to remove material from a solid, the workpiece is cut along a number of axes to achieve a variety of shapes and production of a custom CNC part.

- We use high precision 3 axis milling and 5 axis indexed milling processes to manufacture parts and combined with other advanced capabilities and our experienced team, and more than 30 engineering-grade plastics and metals.

- Our CNC milling machine process produces custom prototypes and end-use production of highly accurate parts in as fast as 5 days and to meet even your most stringent requirements, learn more about how we can support your CNC milling projects with no volume limitations for production.

During the comparison 3 axis and 5 axis mill, manufacturing will be the key decider in your choice, factors including cost, turnaround times, and precision. Of all available CNC machining processes, milling is the most versatile, though we primarily work with metals and plastics, milling also can be done on any rigid material.

3 Axis CNC Milling Services

- 3 axis CNC milling is one of the most widely used techniques to make CNC parts. Because 3 axis CNC milling machines have the composition of the X, Y, and Z axes, can be cut vertically and in any direction, so involves cutting a stationary workpiece along three linear axes: left-to-right, back-and-forth, and up-and-down. Is a relatively simple process, and this is the most common variety of milling machines.

- But for many decades, 3 axis CNC milling machine has been well known to manufacturers and other players in the industrial sector, as well as in many other domains like customers in the aerospace, defense, medical, mold, and commercial markets.

- Using 3-axis CNC milling machine programming is effective for simple geometric designs and very suitable for parts with a simple design and no need for multi-surface machining, a profitable and efficient solution because it is fast and cost-effective.

5 Axis CNC Milling Services

- How 5 axis CNC milling machines create amazing possibilities for our life, it includes all the axes of 4 axis milling, with an additional rotational axis. is the perfect CNC milling technology among all the milling processes at present.

- We use 5 axis milling machine to produce some complex internal designs or models with multi-irregular surface designs, such as artificial bones, aerospace products, car models, and medical products, and use various high-quality metals and plastics.

- We can reach higher cutting speeds without excessive pressure on the cutter to improve overall accuracy and reduce processing time and cost. Get CNC rapid prototyping and small batch CNC machining production parts with better surface finishes.

What types of materials are used in CNC manufacturing?

In order to better assist your project success and to help unlock the potential of your design, we work with professional CNC materials suppliers, material cost is low, and the material selection range is wide, here have we most commonly use materials consisting of both metals and plastics, and even you can compare prices for different machining materials.

Metals: Aluminum, Steel, Alloy, Copper, Brass, Titanium, etc

Plastics: ABS, Polycarbonate, Polypropylene, Delrin, Nylon, Acrylics, etc

Surface Finish Services of CNC Machining

In addition to the choice of the right material that determines the price of your final product, the value can be increased by applying a surface finish, we can provide Surface treatment of different materials to complete your project more perfectly, and we are good at the processing technology has As-machined, Bead Blasting, Anodizing, Electroplating, Polishing, Powder Coating, Brushing, Painting, Black Oxide, Part Marking, etc…

Start A CNC Milling Project Today

At ProtoAces, custom CNC milling services are our AS9100-certified CNC machining facilities designed for moving from rapid prototyping to full-scale production of end-use components. With 50+ CNC machines, we are able to rapidly precision machine your custom-made parts, ensuring your parts are shipped on time, every single time.

PROVIDE EMERGENCY CNC MILLING SERVICES ON ANY REQUEST.

Custom CNC Machining Applications

As a custom precision machining factory, we have extensive experience with manufacturing parts and assemblies for a wide range of industries, we always provide high-quality on-demand manufacturing services to various fields around the world. The following are good at specialized industries served including:

How to work with us

Send parts design files

To start, send us an email file in the supported format. Remark the material and manufacturing process of your choice.

Confirm specs and get a quotation

Get a fair estimate of cost and turnaround time. Configure your part specifications and select a lead time that suits your schedule.

Start Production

After you place an order, we will select the best manufacturer for your order, and take full responsibility for making sure your parts are manufactured according to our standards, production begins immediately.

Parts are Shipped!

Our digital manufacturing process allows us to produce parts as fast as 1 day. Follow up on all order logistics and communications, ensuring your parts arrive on time.