In the parts surface finishing process, bead blasting is a common process, and can be said to be a very important pre-treatment process, many people are not very familiar with the sandblasting process, in fact, it is very common in daily life, which is one of the more affordable surface finishes available.

What is bead blasting?

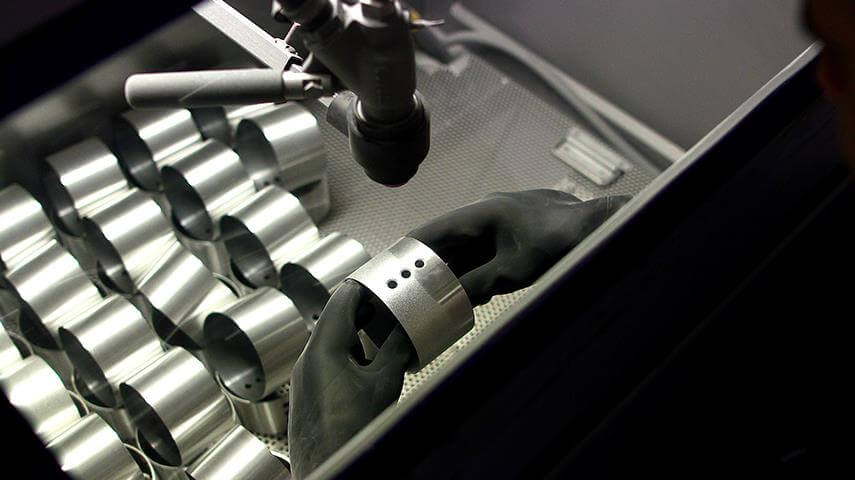

The bead blasting process is simply compressed air as the power to form a high-speed jet beam, at high pressure, using beads to finish a surface. When the beads hit the surface, the impact creates a uniform “dimpling” of the workpiece surface. So that the appearance of the parts’ surface or shape changes.

Due to the impact of the bead blast finish on the surface of the part and cutting, it can clean corroded metal, and remove cosmetic defects like textures and contaminants, the surface of the part can obtain a certain degree of cleanliness and different roughness, increasing the adhesion between it and the coating, extending the durability of the coating film, and also facilitating the leveling and decoration of the coating, so that the mechanical properties of the surface of the workpiece are improved.

Bead blasting material

The most important bead blasting material is the media – glass beads, which come from a lead-free, soda-lime glass shaped into spherical objects. ( bead blasted consumable produced by remanufacturing used flat glass ) glass bead blasting It is an environmentally friendly consumable that we advocate, can be recycle up to 30 times.

In all kinds of abrasive blasting surface treatment consumables, glass beads can produce particles of less than 0.05mm, making the appropriate particle size type and the parts contact area smaller, less likely to damage the surface of the parts, stress relief compared to more uniform, and the matte treatment effect is better. So glass beads are gentler than steel beads and are the primary type of bead used for bead blasting.

Cons – However, larger steel castings with glass beads blasting are “powerless”, and not suitable for tough materials as it may take a longer time. It doesn’t allow for paint adherence because it doesn’t leave a profile (steel bead blasting, on the other hand, can do this).

Ability details of bead blast finish:

Parts coating, parts bonding pretreatment

Remove all the dirt from the surface of the part, such as rust, and establish a very important basic pattern on the surface of the part (i.e., usually called the hairy surface), and can achieve different degrees of roughness by swapping abrasives of different grain sizes, greatly improving the bonding force between the part and the coating and plating material. Or make the bonding parts bond more firmly and of better quality.

Castings and forgings rough surface, heat treatment after the cleaning and polishing

Clean up all the dirt (such as oxide, oil, and other residues) on the surface of the part after casting and forging, heat treatment, and polish the surface of the part to improve the finish of the part and play a role in beautifying the part.

Cleaning can make the workpiece reveal uniform and consistent metal color, so that the appearance is more beautiful, to beautify the role of decoration.

Machined parts burr cleaning and surface beautification

Clean up the tiny burrs on the surface of the parts and make the surface of the parts flatter, eliminating the harm of burrs and improving the grade of the parts. And beadblast can make very small rounded corners at the junction of the workpiece surface, making the part appear more beautiful and precise.

Improve the mechanical properties of the parts

Can produce a uniform fine bumpy surface on the surface of the parts, so that the lubricant is stored, so that the lubrication conditions improve, and reduce noise to improve the service life of machinery.

The role of light finishing

- Polish the surface of various parts to make the surface of parts more beautiful.

- So that the part achieves smooth and non-reflective requirements.

For some special-purpose parts, sandblasting can achieve different reflective or matte at will.

Stress relief and surface strengthening

Bead pellets hit the surface of the parts to eliminate stress and increase the surface strength of the parts, such as springs, machining tools, aircraft blades, and other workpiece surface treatments.

It is in various applications with bead blast finish in many industries. In different parts of the surface treatment sandblasting shot blasting process, in the selection of abrasives, glass beads are widely used to clean the impurities on the metal surface and strengthen the material for treating the metal surface, also glass beads are often used in all kinds of stainless steel products matte treatments, the practical uses range is wide, including aerospace components before painting, automotive parts, consumer manufacturing parts, casting parts, and materials parts of medical.

If you’re seeking a reliable, eco-friendly, and cost-effective way for the best bead blast finish on your parts, you should contact us now and get your instant quote.